Brief :

-

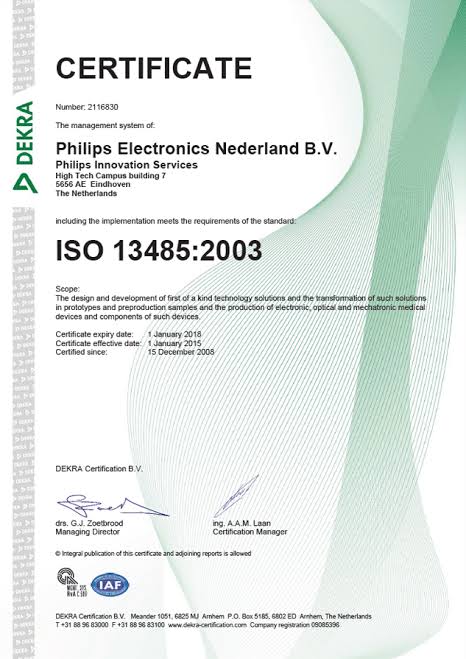

- • The primary objective of ISO 13485:2003 is to facilitate harmonized medical device regulatory requirements for quality management systems. As a result, it includes some particular requirements for medical devices and excludes some of the requirements of ISO 9001 that are not appropriate as regulatory requirements.

• This international standard is based off the ISO 9001 international standard with specific requirements to meet regulatory needs. This standard, applicable on a voluntary base, was designed in particular for medical device manufacturers; ISO 13485 addresses most or all of the quality system requirements in markets including Europe, Australia, Japan and Canada. The US Food and Drug Administration does not formally recognize ISO 13485 certification, but US Good Manufacturing Practices quality system requirements overlap with the standard in many areas. ISO 13485 is also the basis for quality system regulations in other markets such as South Korea and Brazil.

• However, it is important to note that while ISO 13485 is an international standard, certification in Europe, for example, does not mean your ISO 13485 certification is valid in other markets such as Canada or Japan. Many countries impose their own additional QMS requirements on top of those outlined in the standard. You must meet those additional requirements – on top of ISO 13485 – to be certified to sell in those markets.

Benefits :

-

-

- • Optimum Utilization of Resources.

-

- • Bring result oriented approach.

-

- • Access to new markets

-

- • Reduce operational costs

-

- • Proven commitment to quality

-

- • Adds transparency to the way complaints, surveillance or product recalls are handled

-

- • Increased Customer & Stake Holder Satisfaction.

-

- • Employee Role Clarity, increased transparency & accountability.

-

- • Effective Systems and Quality Procedures resulting in Streamlined Workflow and Improved Quality of Work.

-

- • Satisfying Customers through Consistent High Level of Product/Service Quality.

-

- • Reduction in Wastage, Rejection and Rework.

-

- • Enhanced Image in the Market.

-

- • Encouragement to Learning, Team Work and Coordination.

-

- • Increase profitability.

-

- • Establish fact-finding mechanism with proper identification and traceability.

-

- • Provide Continual Improvement at all level.

-

- • Systematic approach leads you to commit less no. of mistakes.

-

- • Provide clear idea about your strengths & weakness.

-

- • Provide control methods for measurement and monitoring of processes and products

-

- • Structures the operations of the organization to achieve a desire result

Applicability :

- • Medical Devices Manufacturer